PROVEN AUTOMATION EXPERTISE

KAC offers engineering and technical services that specialize in automation for the manufacturing and process industries. We are a Recognized Rockwell Automation System Integrator and ABB Robotics value solution partner.

INTEGRATION AND RETROFITTING

Case Studies

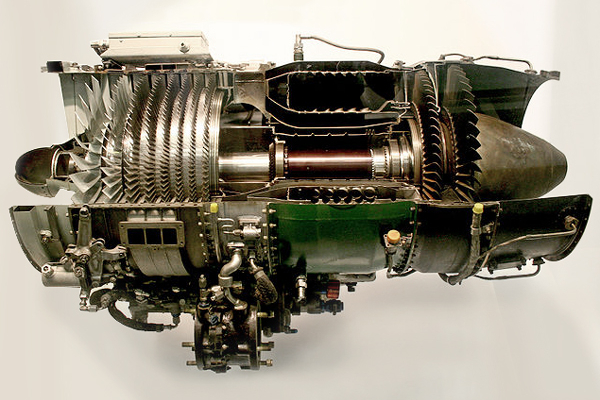

ROBOTIC INTEGRATION & END OF ARM TOOLING DESIGN

Kredit Automation and Controls completely retrofit the controls on a system that produces molds for casting. The customer manufactures turbine engine components. The old control system was a functional but aging system based on a Vulcan Engineering Electrobot robot, an Allen-Bradley SLC-500 PLC, and a Visual Basic program.

PRINTING BARCODES DIRECTLY FROM A PLC PROGRAM

The L-Shear uses servos to position large laminated copper sheets under a shear to cut them into precise sizes used for circuit boards. One goal of a recent control system retrofit was to allow bar code printing to be controlled by a PLC without requiring a computer or operator data entry. This machine is a limiting factor in plant production speed. This meant that plant production was impacted when data entry errors necessitated a special re-run through the L-Shear to reprint. The ability to print a barcode while the sheet is in motion and the reduction in scrap and rework due to data entry errors was a key accomplishment of the retrofit.

AEROSPACE AND CHEMICAL PROCESSING

In 2011 Kredit Automation was contracted to upgrade the controls on a system with two important processes: Fluoride Ion Cleaning and Chemical Vapor Deposition. This important revenue generating system had a robust Allen Bradley PLC-5 based core design, but fifteen years of continuous use was starting to manifest increasing maintenance and repair incidents and downtime.

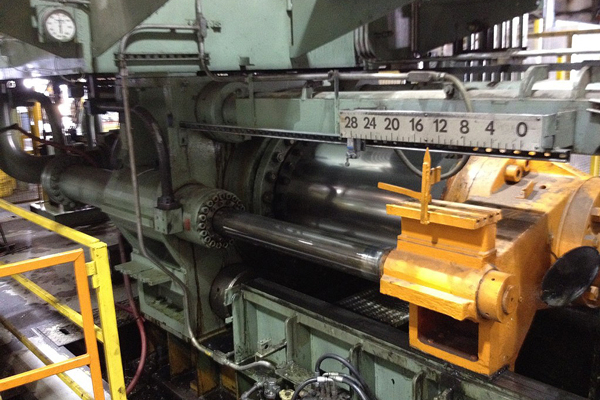

EXTRUSION PRESS CONTROL SYSTEM RETROFIT

Kredit Automation has done over a dozen aluminum extrusion press control system retrofits. Extrusion presses last for decades and periodically need a new control system. Protection against obsolesce and parts unavailability are always motivating factors. Sometimes the owner also wants to make changes to the controller programs and operator screens.

EMERGENCY CONTROL SYSTEM REPLACEMENT

A fire destroyed the entire control system for the melting and holding furnaces at the cast house plant of an aluminum extruder. Panels, controllers, terminations, operator interfaces…everything destroyed. Production halted. The plant needed a new control system ASAP. Kredit Automation and Controls was asked to help make it happen.